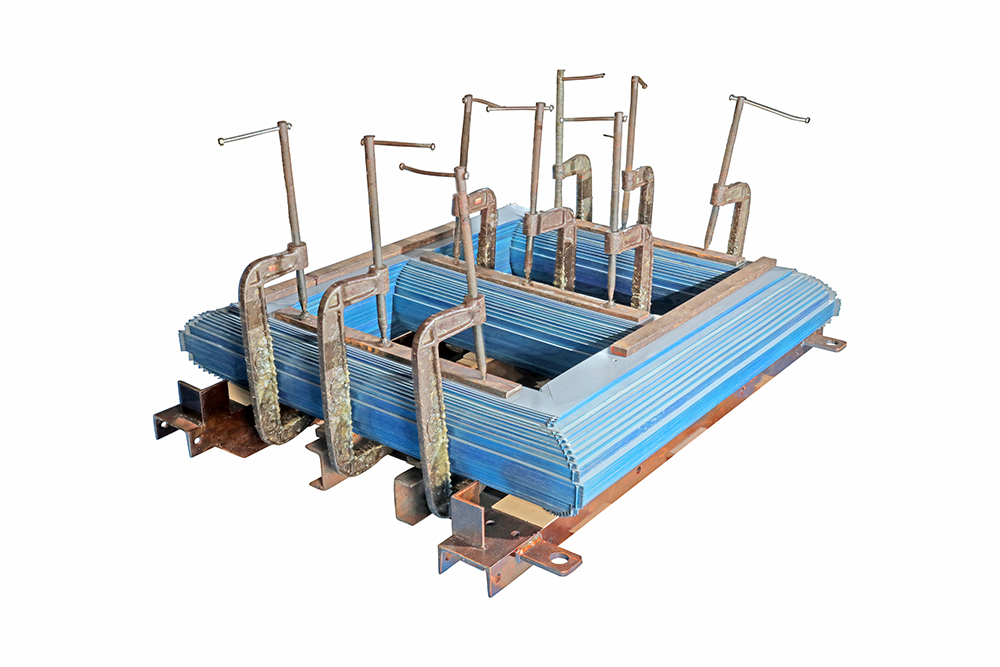

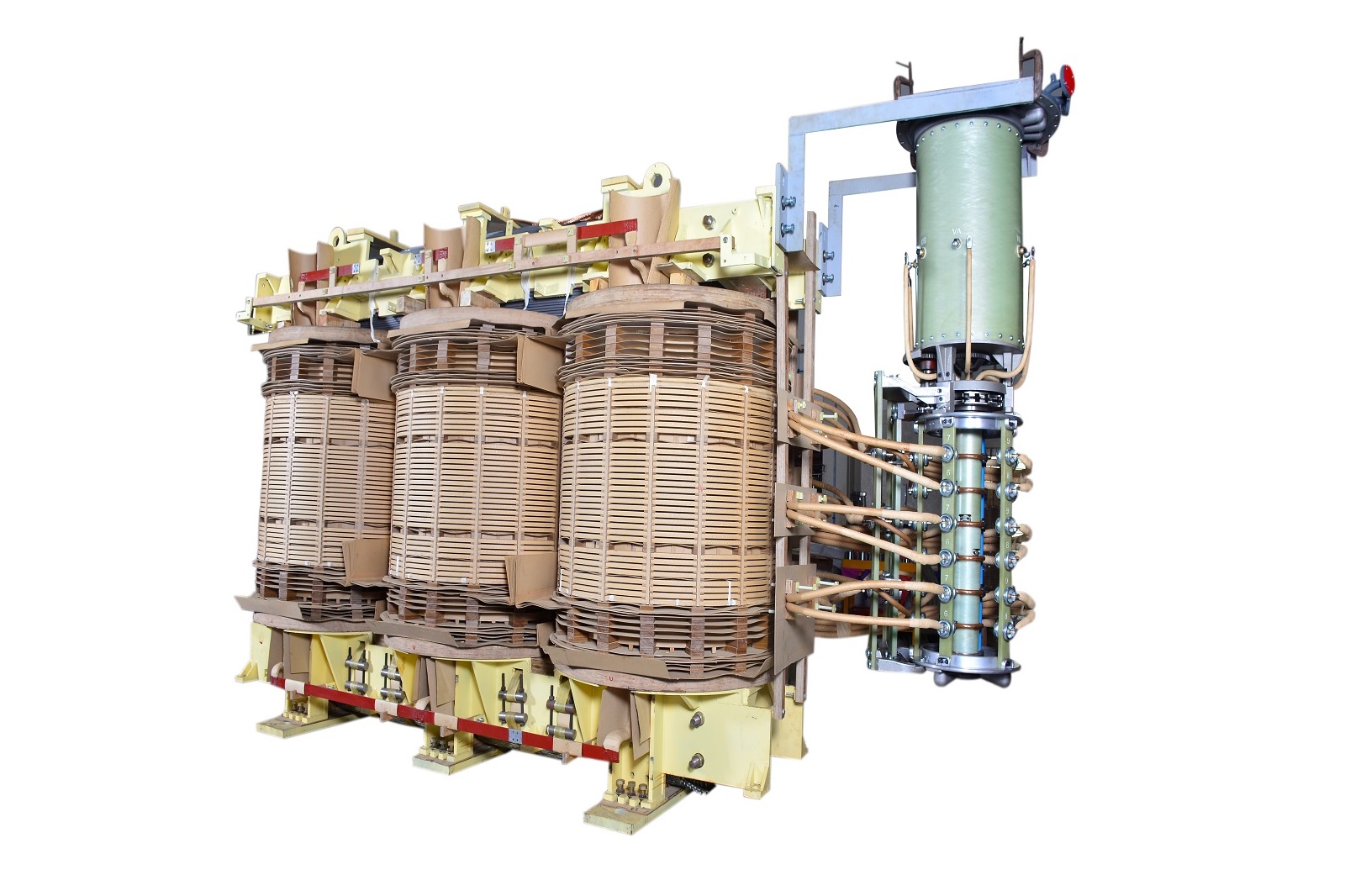

This is the main assembly frame. The assembly consists of the core, clamping structure, Feet, and the supporting structure for the framework to support tap and line terminals.

The core plays a vital role in selecting the material. The core material is manufactured from Cold Roll Grain oriented silicon steel sheets, available in various thickness and grades. The grade defines the material lost per kilogram while energizing the transformer. The increasing tariff of power has compelled manufacturers to build economical transformers and also design them for optimum losses.

The core mitered and assembled in step lap formation. The mitered joints are provided with minimum gap.

The clamping structure is a fabricated steel frame made from standard IS angle, channels or plate construction. The frame is held vertically and horizontally using tie rods. The vertical tie rods also exert adequate force on the coils during clamping to counter the stresses generated during operation. The transformer rests on its feet. The clamping structure supports the framework to route tap and line terminals.

sales@kprsindia.com

sales@kprsindia.com  +91- 080-42077095

+91- 080-42077095